Blog

Cummins ISX Anti-Polishing Ring Piston Removal and Replacement

Guide to Cummins ISX Anti-polishing Ring piston removal and replacement

If you have worked on a Cummins ISX engine you will have figured out it is impossible to insert a piston with rings from the top of the liner.

To install the piston rings, ATC7040 (fig 3) a piston ring compressor is required to install the piston, rings and connecting rod assembly into an anti-polishing ring cylinder liner.

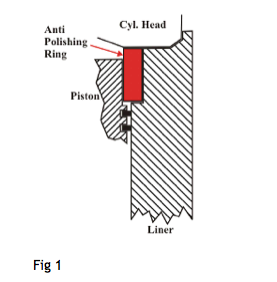

The piston, piston ring, and connecting rod will not install into the anti-polishing liner with the anti-polishing ring installed. The inside diameter of the anti-polishing ring (fig 1) is smaller than the than the actual engine liner bore so the piston with rings can not pass through the anti-polishing ring.

To replace the piston, piston rings and connecting rod in the Cummins you must first remove the anti-polishing rings. M20187 (fig 2) can be used to remove the anti-polishing rings from the cylinder liner. Removing the anti-polishing rings can usually be done by hand but when they are difficult to remove you place the snap ring supplied in the M20187 under the anti-polishing ring and rotate the engine. The M20187 includes two snap rings so two anti-polishing rings can be removed on each rotation of the engine. You can now place the special spacer ring included in the M20187 into the top of the liner and install the piston, piston rings and connecting rod as you do in any other engine. When installed, remove the spacer insert the anti-polishing ring and move to the next cylinder.

The ATC 529948 (fig 4) is the equivalent of the Cummins kit and will give you everything you need to install the piston rings in the Cummins ISX.

As always please refer to your owner’s manual for the most up to date procedure.