Blog

Hydraulic Clutch Maintenance

Most vehicles do not have any specified service interval for replacing the clutch fluid. However, when the fluid is replaced periodically for preventive maintenance, it can prolong the life of the hydraulic clutch system, especially the slave cylinder. If the fluid looks discolored or cloudy, it is contaminated and must be changed. The condition of the fluid can be ascertained by using a brake fluid chemical test strip, which changes color and indicates the condition of the fluid.

Sometimes, the hydraulic clutch system may mistakenly be contaminated by other fluids such as ATF, PS fluid, motor oil, coolant, etc. The system then has to be drained and flushed to prevent major system damage. It must then be refilled with the proper fluid specified by the manufacturer.

Bleeding the hydraulic clutch system can be a difficult proposition. It depends on whether the slave cylinder has a bleeder screw in a convenient location. Special bleeder tools such as the Phoenix Injector or the Hydraulic Injection System SHOOTER can make the job easier to handle. The former is a hand-held unit for removing air from the system while the latter is a complete system that includes the full gamut of adapters and accessories for flushing and bleeding most hydraulic systems.

For a reverse fluid bleeding, you must first flush the hydraulic system. That means completely purging the system of all the old brake fluid. This makes sure you have a lasting repair.

Flushing the System with the SHOOTER

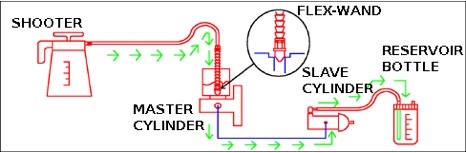

Connect the 16-oz reservoir bottle to the bleeder screw of the slave cylinder. Next, insert the discharge hose of the SHOOTER (with the flex-wand attached) into the fluid inlet port of the master cylinder and hold it firmly in place. Fill the SHOOTER with the appropriate fluid and pressurize it.

Discharge the fluid into the system by simply depressing the trigger on the handle of the shooter. Consider the system flushed after about 6- to 8-ozs of fluid has been discharged. However, the amount of fluid necessary for flushing may depend upon the plumbing of the systems hydraulics.

Therefore, repeat this process until new fluid starts to accumulate in the reservoir bottle from the slave cylinder. This ensures that the entire system has been flushed thoroughly. Now the system is ready to bleed using the reverse fluid bleeding method.

Reverse Fluid Bleeding

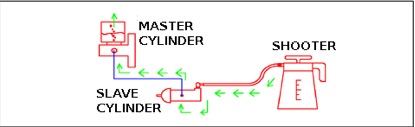

First, remove most of the fluid from within the master cylinder reservoir. Using an appropriate bleeding adapter, connect the discharge hose of the SHOOTER to the bleeder screw of the slave cylinder and open the screw. Inject approximately 5- to 6-ozs of fluid into the hydraulic system by depressing the trigger on the handle of the SHOOTER. The fluid will first fill the slave cylinder and then rise in the master cylinder. The rising fluid will carry any trapped air and vent it into the master cylinder.

As you have already removed fluid from the master cylinder reservoir earlier, the rising fluid prevents any possible over-filling of the reservoir. This is necessary to prevent spillage, as brake fluid is corrosive and measures should be taken to prevent it from coming into contact with the body of the vehicle, as it is certain to damage the paint and finish. In case this happens, remove the brake fluid immediately with soft cloth and wash the area clean with water.

For ensuring the full service life of the clutch and disc, critically examine and replace all worn clutch system components. Most commonly, the parts which need to be examined and which are susceptible to damage are: fork pivot, cross shaft bushings, bearing retainer, linkage, fork, cable, slave and master cylinder and the flywheel. When you replace worn or damaged parts, the procedure is inexpensive insurance against comebacks.

Leaking fluids at the slave or the master cylinder or in the hose or line that connects these two components together may also cause major problems. Because of fluid loss, the system may not be able to generate enough pressure for disengaging the clutch. Air may also enter the system and replace the lost fluid, creating bubbles that increase the pedal travel until the clutch fails to release.