Blog

Proper Care and Repair of the Top Deck Counterbore Tool

We often receive calls from customers saying "I need my counterbore tool rebuilt." One of the largest complaints is that it is no longer cutting flat. This blog will give one simple and easy way to fix this problem without buying a new tool or sending your tool out for a rebuild.

This method will work with both the Porta-Tool/Kent-Moore shim cutter as well as the Apex /Monaco Tool. The number one factor cnausing this is over torquing. This tool needs to be torqued to 20ftlbs. The Kent-Moore counterbore tool is has a cast iron base plate, while the Apex counterbore tool has a forged base plate. It can withstand a little more abuse but over torquing will warp these base plates. It is very vital that you do not over torque this tool.

The first step should be the easiest. Inspect the base plate of your counterbore tool for any damage or foreign matter. I have seen these tools with rust and dings all over the bottom of the base plates. This is a precision tool so never toss it around. You also need to look at your cutter plate. If it has a ring cut around the plate it will have to be replaced. Never turn the cutter plate when centering your tool. Use gentle pressure on the plate and make sure you have space between the depth set collars and the top of the tool.

The next step we want to take is to mark one side of the tool. We will now bolt it down and cut a few thousands off the counterbore ledge.

Now remove the tool and measure all the way around the counterbore ledge noting the high or low points. If one side is lower than the other make a note of the difference. We are now going to turn the tool around and cut a few more thousands and check if the opposite side is now low. Sometimes the problem is not with the tool but with the block deck. By rotating the tool and making several test cuts you can track if you truly have a problem with your tool.

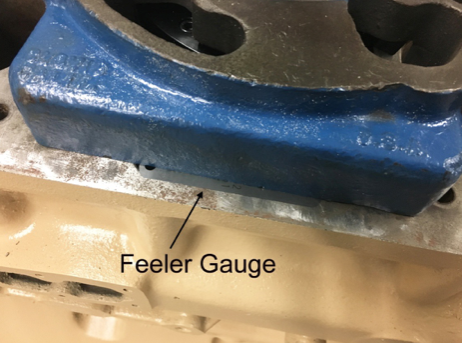

If the counterbore stays out of flat only on one side of the block when you rotate the tool, the problem is in the block deck and you can fix this problem by adding a feeler gauge under the base plate. This can also be done to fix a tool that is cutting out of flat. This is a fast but not permanent repair for a damaged tool.

If your tool is consistently cutting low on one side you can shim the tool back into flat. This can be done with trimming down a feeler gauge to fit between the base and drive unit. The old school method is to use the cellophane from a cigarette pack. Be very careful when loosening the bolts. You will need to do additional test cuts to make sure that you do have the tool back cutting flat.

If your counterbore tool is cutting out of round or if it cuts out of flat but will not repeat unfortunately it is time for a new tool. Do not think of how much this is going to cost to replace, think about how many blocks this tool has cut.

These tools should last for many years with just some basic maintenance.

Best practices:

Keep the tool clean and store it in a temperature controlled environment. These tools do not like to work when they are cold. If it is cold and hard to turn, you are causing undo wear on the bushings.

I like to keep a thin coating of lubriplate on the shaft of our machines.

Never use an impact to tighten down and these tools should always be torqued down.

You will also want to use care in tightening the thumb screws on the depth set collars. These do have thread protecting buttons under them. They need to be checked every so often.

With proper care you should get many years life out of your counterbore tool. I have had many used Porta-Tool Green machines come to us used that even though made in the 1970’s are still cutting as good as a new machine. Use this guide on PT2250, PT2200, PT2205, PT2210, M50133, M50134, M50139, M50145 and all Porta Tool CBU tools

If you’re ever in Columbus, Indiana, you can stop in and see an original Cummins 5 1/8” counterbore machine in our lobby. This was one of the first machines ever made by Porta-Tool International. Feel free to contact us with any questions.

And as always happy wrenching -

Fred