Blog

Diesel Ring Compressors

There are three basic types of diesel ring compressors: the universal band type, tapered sleeve and clamshell. All three have their advantages and disadvantages.

Universal Band Type Ring Compressor

This is probably the most common ring compressor in the marketplace. It has its advantage of being universal and inexpensive. Bu it is also very hard to use and requires a lot of care and patience to properly install piston rings.

Tapered Sleeve Ring Compressor

The tapered sleeve ring compressor was created to help take the guess work out of installing diesel rings. The main advantage it has is it simplifies the process. Just install your rings, give everything a good coat of oil and push it through the cone.A block of wood and a hammer have even come into play with this style. I would not try that with a band type.

Clam Shell Ring Compressor

It took a few years but finally they got it right. The basic principle is you install your rings on the piston and slowly squeeze the clamshell ring compressor closed. When the rings are properly seated on the piston, the small pin on the ring compressor will drop into place. Don't forget to give everything a good coat of oil first. Then you just push the piston in the liner like the tapered sleeve. I have seen this style with 2 handles or just one. The only thing you need to watch for is that I have seen some of these made out of aluminum. This is a really bad idea.

Locking Clamshell Ring Compressor Variant

I have always heard that any man can make a mistake but if you really want to make a mess of something, bring in an engineer. With that, we bring you the mutant form of the clamshell ring compressor. This ring compressor was designed for the EGR Version of the 60 Series Detroit. For some reason, someone --- not naming any names (engineer) --- thought it would be a great idea to make the bottom of the con rod larger that the bore of the engine. So now, the piston and rings must be installed through the bottom of the liner on a work bench and not in the engine. We will not even talk about trying to pull one of the liner that has welded itself to the block. Good, bad or just a way for Detroit to sell pre-assembled liner packs, it is what it is and we have to live with it.

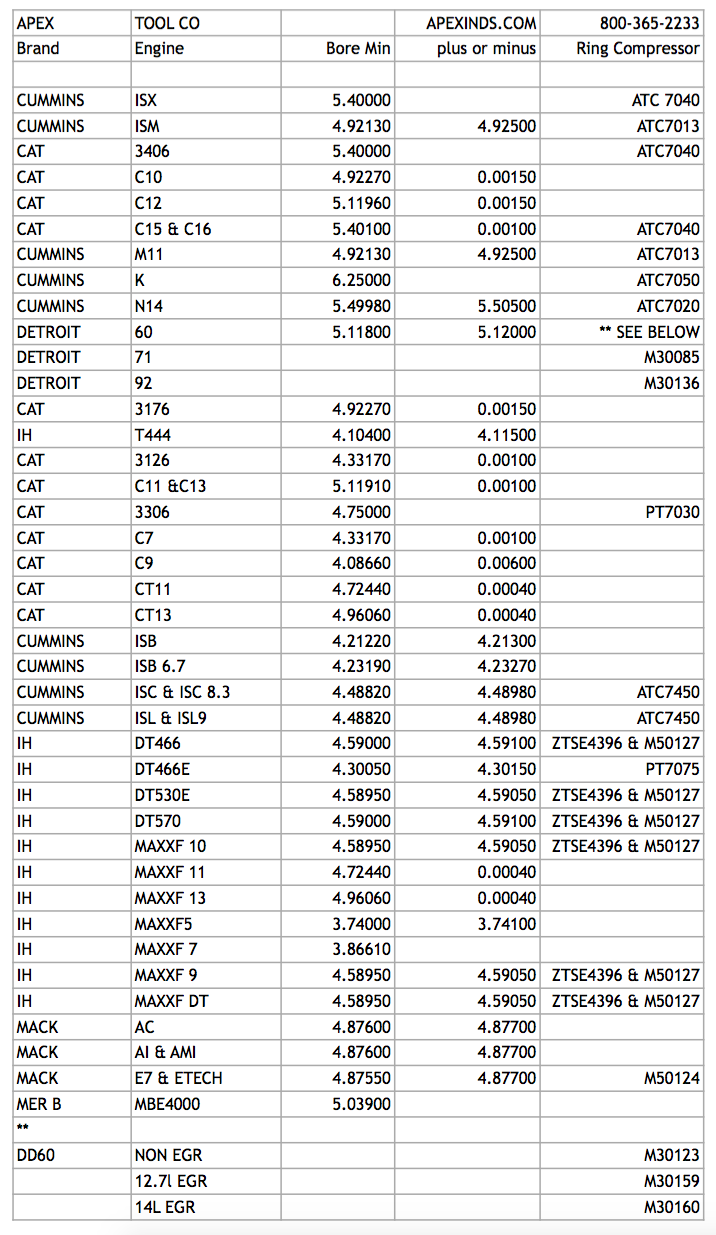

Below is an internal cheat sheet I created for our employees. Take it for what it is worth. As always please refer to your service manual for the most current information.

overall rating:

my rating:

log in to rate