Blog

Cummins ISX QSX Cam Bearing Installation Procedure: ATC 3164088 Professional Guide

Detailed cam bearing procedure for Cummins ISX/QSX using ATC 3164088 kit.

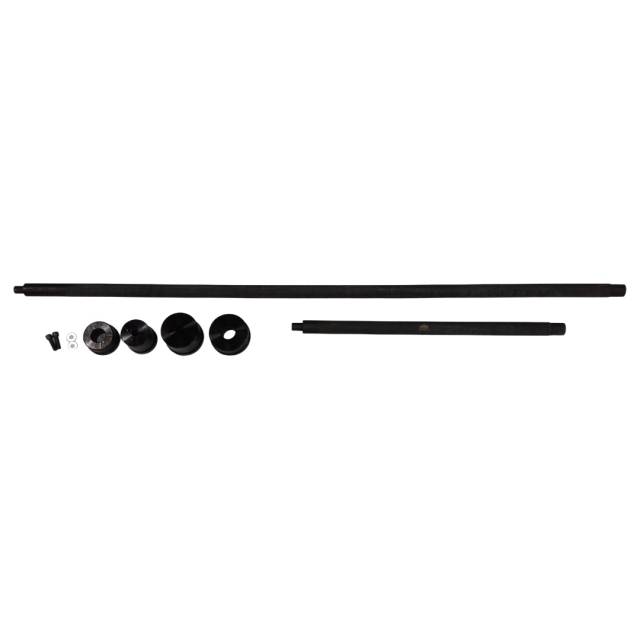

This 12-phase procedure uses the ATC 3164088 kit to remove and install cam bearings on Cummins ISX/QSX engines. Ensures aligned, damage-free service with 24″ & 55″ drivers for full reach.

Introduction: Essential Cam Bearing Service for Cummins ISX/QSX Engines

Proper cam bearing installation in ISX/QSX prevents oil starvation. The ATC 3164088 kit provides adaptors and long drivers—critical for aligned, smooth results.

Phase 1-3: Engine Preparation & Bearing Removal

- Secure engine and remove camshaft – Access bearings

- Clean bearing bores – Remove debris

- Inspect bores & bearings – Note scoring

- Select correct adaptor – Match bearing size

- Attach driver bar – 24″ or 55″ as needed

Phase 4-6: Bearing Extraction

- Insert adaptor into bearing – Seat fully

- Apply controlled force – Steady hammer strikes

- Remove bearing carefully – No bore damage

- Clean bore thoroughly – Solvent & brush

- Measure bore diameter – Verify spec

- Document removal – Photos/notes

Phase 7-9: New Bearing Installation

CRITICAL: ATC 3164088 Installation Setup

- Lubricate new bearing – Even coating

- Position bearing on adaptor – Align square

- Use driver bar to install – Even force

- Seat bearing flush – Check depth

- Verify alignment – No distortion

- Repeat for all bearings – Consistent

Phase 10-12: Reassembly & Testing

- Reinstall camshaft – Torque spec

- Refill oil – Check level

- Start idle test – Monitor pressure/noise

- Road test load – Verify performance

Critical Safety Warnings: Cam Bearing Procedure

MUST AVOID THESE FATAL ERRORS:

- ❌ Never misalign adaptor – Scores bore ($1.5K+)

- ❌ Never unclean bore – Contam ($2K+)

- ❌ Never excessive force – Distorts bearing

- ❌ Never skip lube – Galling

- ❌ Never omit depth check – Misalignment

- ❌ Never ignore spec – Failures

- ❌ Never ignore PPE – Hammer risks

Professional Service Documentation

Why ATC 3164088 Outperforms Improvised Drivers

Risky Improvised Methods:

- ❌ Generic drivers → Bore scoring ($1.5K+)

- ❌ Short bars → Uneven force

- ❌ 3–6 hour struggles → Labor losses

- ❌ Misalignment → Bearing crush

- ❌ No kit → Failures

ATC 3164088 Advantages:

- ✅ 24″ & 55″ reach

- ✅ Precision adaptors

- ✅ 80% less damage

- ✅ Smooth transitions

- ✅ Protects $12,500–$29,500

- ✅ Heavy-duty

- ✅ Full kit coverage

- ✅ Shop proven

Install Cam Bearings Professionally. Preserve Cummins Bores. Maximize Engine Life.

Get ATC 3164088 – $602.07

overall rating:

my rating:

log in to rate