Blog

How to use a vise

In the tool room or the workshop, a vise is an indispensable tool, often called the third hand. This is because a vise usually holds a work piece or material in place, leaving both hands free to work on the material. To enable stability of the work piece, vises are usually mounted on firm supports such as workbenches.

Vises are versatile tools useful for a wide variety of work. Different types of vises are available and you can choose from tradesman types, combination types, mechanics type, machinists' type and utility types among the most popular ones. The machinists' bench vise is geared more for the professional user. These are available in a variety of sizes along with a stationary or a locking swivel base. It also has an extra deep throat that gives more working room and its jaws opens wider. The two factors that define a vise are its jaw opening and its tensile strength. For example, a machinist vise may have a 12-inch jaw opening with a tensile strength of 60,000 psi. In most bench vises, you can replace the jaws.

How to Use a Vise Safely

When using a striking tool or a power tool on a work piece held by a vise, it is advisable to wear a face shield or safety goggles.

Check that the vise is attached securely. There must be bolts in all the holes in the base of the vise. There must be lock washers under the nuts. Make sure the bots are properly tightened. Ensure that the workbench is firmly secured to its base.

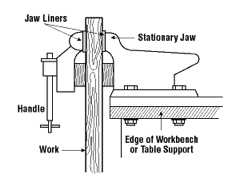

The vise should be mounted such that its stationary jaw projects a little beyond the edge of the workbench. This makes it easy to clamp a long work piece in the vise without the edge of the workbench interfering.

Before attempting to clamp a work piece in a vise, check the jaws for damage or cracks. Select a vise that is large enough to hold the work piece without strain.

When placing the work piece in the vise, position it such that the entire clamping surface of the jaw can support the work piece. For sawing, filing the work piece, keep the work point close to the jaws of the vise, as this will prevent vibrations.

If the work piece is extra-long, it may be necessary to support the end with an adjustable stand, a box or a sawhorse. This will remove the extra strain from the vise.

Caring For a Vise

All threaded and moving parts must be kept clean, lightly oiled and free of debris and dirt. You may have to use jaw liners to prevent jaw marks on it if the work piece is of soft material. Replace any worn jaw insert and a bent handle.

What Not To Do With a Vise

– Never weld the base of a vise to any metal such as the metal top of the workbench.

– Never attempt to repair a broken vise jaw by welding or brazing.

– Never attempt to bend a heavy rod by clamping in a light vise.

– Never cut into the jaws of a vise.

– Never apply a heavy load at the corner of the jaws of a vise.

– Never use an extension (a pipe) for exerting extra pressure.

– Never hammer on the handle for extra tightening.

– Never use the jaws as an anvil.

– Never use a vise that has even the slightest crack.

– Never unscrew or open the jaws more than they were designed for.

overall rating:

my rating:

log in to rate